BEAVER CNC

On the Eagle board above, note the map of parts.

Downloadable files for BEAVER CNC <<-- Here

Marlin for Ramps 1.4

Lines changed or consider changing in the Configuration.H file:

77: #define STRING_CONFIG_H_AUTHOR "(BeaverCNC Team 10/May/2018)"// Who made changes when.

122: #define MOTHERBOARD BOARD_RAMPS_14_EFB // Where we declared Ramps1.4 as the Mother Board we're using

127: #define CUSTOM_MACHINE_NAME "Beaver CNC" // Naming the machine

137: #define EXTRUDERS 1 // no extruders but use the E command in G code to control direction of the Nibbler

289: #define TEMP_SENSOR_0 1 // add later thermistor to control temp on the tip of the nibbler's head - Also had to have this to one. Zero failed to compile.

341: //#define PIDTEMP // uncomment this to enable PID. Do it if a a nozzle is installed

342: #define BANG_MAX 0 // Limits current to nozzle while in bang-bang mode; 255=full current; I set it to 0 to limit current to nozzle, since we havnt got one

394: #define MAX_BED_POWER 0 // limits duty cycle to bed; 255=full current; I set to zero

421: //#define PREVENT_COLD_EXTRUSION // Uncomment when adding hot-end

422: //#define EXTRUDE_MINTEMP 0 // was 170

//Endstops:

475: //#define USE_ZMIN_PLUG // UnCommented it since no working - Had to have this on. Why? Maybe add a jump wire to have Z end stop always on

476: #define USE_XMAX_PLUG // I Uncommented it to include xmax endstop

477: #define USE_YMAX_PLUG // I Uncommented it to include ymax endstop

//End-Stops:

495: #define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. I changed this to True. Pushed Endstop was reading Open.

496: #define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. I changed this to True. Pushed Endstop was reading Open.

498: #define X_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

499: #define Y_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop.

-Compare these (till 559) below with the next table "feeds and speeds"

532: #define DEFAULT_AXIS_STEPS_PER_UNIT { 200, 75, 4000, 80 } // x was 80 and was driving 40mm when told to drive 100mm on software

// y was 80 as well, was driving 107mm Real when sending 100mm

539: #define DEFAULT_MAX_FEEDRATE { 500, 500, 5, 500 }

547: #define DEFAULT_MAX_ACCELERATION { 800, 800, 100, 800 }

557: #define DEFAULT_ACCELERATION 300 // X, Y, Z and E acceleration for printing moves

558: #define DEFAULT_RETRACT_ACCELERATION 300 // E acceleration for retracts

559: #define DEFAULT_TRAVEL_ACCELERATION 300 // X, Y, Z acceleration for travel (non printing) moves

569: #define DEFAULT_XJERK 5.0 // was 5

570: #define DEFAULT_YJERK 5.0 // was 5

751: #define INVERT_X_DIR true // inverted DIR was needed

752: #define INVERT_Y_DIR true // Keep that in mind if invert DIR needed

753: #define INVERT_Z_DIR false // Keep that in mind if invert DIR needed

760: // For direct drive extruder v9 set to true, geared extruder set false.

761: #define INVERT_E0_DIR false // For the E motor for the Nibbler's rotation

774: // Direction of endstops when homing; 1=MAX, -1=MIN // If needed

774: // :[-1,1]

776: #define X_HOME_DIR -1

777: #define Y_HOME_DIR -1

1109: // EEPROM

//

// The microcontroller can store settings in the EEPROM, e.g. max velocity...

// M500 - stores parameters in EEPROM

// M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily).

// M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to.

This is a table we should keep in mind when trimming Feeds and Speeds:

Starts at line 507 of Configuration.H of Marlin Firmware (Open with Arduino IDE)

//=============================================================================

//============================== Movement Settings ============================

//=============================================================================

// @section motion

/**

* Default Settings

*

* These settings can be reset by M502

*

* Note that if EEPROM is enabled, saved values will override these.

*/

/**

* With this option each E stepper can have its own factors for the

* following movement settings. If fewer factors are given than the

* total number of extruders, the last value applies to the rest.

*/

//#define DISTINCT_E_FACTORS

/**

* Default Axis Steps Per Unit (steps/mm)

* Override with M92

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 4000, 500 }

/**

* Default Max Feed Rate (mm/s)

* Override with M203

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_MAX_TE { 300, 300, 5, 25 }

/**

* Default Max Acceleration (change/s) change = mm/s

* (Maximum start speed for accelerated moves)

* Override with M201

* X, Y, Z, E0 [, E1[, E2[, E3[, E4]]]]

*/

#define DEFAULT_MAX_ACCELERATION { 3000, 3000, 100, 10000 }

/**

* Default Acceleration (change/s) change = mm/s

* Override with M204

*

* M204 P Acceleration

* M204 R Retract Acceleration

* M204 T Travel Acceleration

*/

#define DEFAULT_ACCELERATION 3000 // X, Y, Z and E acceleration for printing moves

#define DEFAULT_RETRACT_ACCELERATION 3000 // E acceleration for retracts

#define DEFAULT_TRAVEL_ACCELERATION 3000 // X, Y, Z acceleration for travel (non printing) moves

/**

* Default Jerk (mm/s)

* Override with M205 X Y Z E

*

* "Jerk" specifies the minimum speed change that requires acceleration.

* When changing speed and direction, if the difference is less than the

* value set here, it may happen instantaneously.

*/

#define DEFAULT_XJERK 10.0

#define DEFAULT_YJERK 10.0

#define DEFAULT_ZJERK 0.3

#define DEFAULT_EJERK 5.0

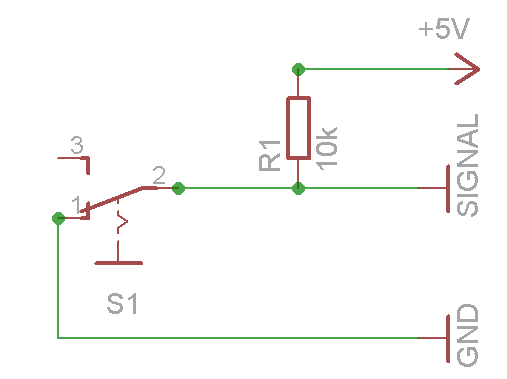

The reason there are 3 pins for Endstops is for a pullup resistor.

I hacked a Pullup system using a SMD 10k Ohms Res, soldered it from the VCC pin to the

Signal pin, and GND in the middle:

|VCC|GND|SIGNAL|

Good link for Ramps wiring also:

https://www.drdflo.com/food-printer-frame/

http://reprap.org/wiki/File:Rampswire14.svg

http://reprap.org/wiki/RAMPS_1.4

http://doc.3dmodularsystems.com/electronic-wiring/

What to do with it:

Metal Etching